Engagement as M&E experts for program by UNICEF for Behaviour Change initiatives in 100 schools

CLIENT

Research Centre for Urban and Environmental Studies (RCUES)

Research Centre for Urban and Environmental Studies (RCUES)

World Resource Institute (WRI), India

EPR stands for Extended Producer Responsibility, which is a policy framework that makes producers responsible for managing the end-of-life disposal of their products. The objective of EPR is to ensure that the producers take responsibility for managing the environmental impact of their products, including the waste generated by their products.

In the Indian scenario, EPR has been implemented for several products such as e-waste, plastic waste, and hazardous waste. The E-waste (Management) Rules, 2016, requires producers of electrical and electronic equipment (EEE) to collect and manage e-waste generated by their products. Similarly, the Plastic Waste Management Rules, 2016, requires producers of plastic products to take measures for collecting, segregating, and disposing of the plastic waste generated by their products.

The implementation of EPR in India has helped in reducing the environmental impact of products and has also led to the development of a recycling industry. However, there are still challenges in the effective implementation of EPR, such as the lack of infrastructure for the collection and disposal of waste, lack of awareness among consumers, and the need for more stringent regulations to ensure compliance

In India, EPR policy implementation is at different stages for different types of waste.

The E-waste (Management) Rules, 2016, make producers responsible for the collection and management of e-waste generated by their products. The e-waste (Management) Rules, 2016, also cover the management of CFL and other mercury-containing lamps.

Reading Material: Policy Guidelines on e-Waste

The Plastic Waste Management Rules, 2016, require producers of plastic products to take measures for collecting, segregating, and disposing of the plastic waste generated by their products.

Reading Material: Policy Guidelines on Plastic Waste

The Batteries (Management and Handling) Rules, 2001, require battery manufacturers and importers to take responsibility for the collection and disposal of their waste batteries.

Reading Material: Policy Guidelines on Battery Waste

The Hazardous and Other Wastes (Management and Transboundary Movement) Rules, 2016, require the producers of hazardous waste to take responsibility for the safe disposal of their waste.

Reading Material: Policy Guidelines on Hazardous Waste

The EPR policy for e-waste in India is regulated by the Ministry of Environment, Forest and Climate Change (MoEFCC) under the E-Waste (Management) Rules, 2016. The EPR targets for e-waste management have been set by the Central Pollution Control Board (CPCB) for the following categories:

Currently, there are over 100 companies in India that have implemented EPR policies for e-waste, including Dell, HP, Lenovo, Apple, Samsung, LG, etc. These companies have tie-ups with authorized e-waste recyclers to collect and dispose of their e-waste.

The EPR policy for plastic waste in India is regulated by the MoEFCC under the Plastic Waste Management Rules, 2016. The EPR targets for plastic waste management have been set by the CPCB for the following categories:

Currently, there are several companies in India that have implemented EPR policies for plastic waste, including Coca-Cola, PepsiCo, Nestle, Unilever, etc. These companies have tie-ups with authorized recyclers to collect and dispose of their plastic waste.

The EPR policy for paper waste in India is regulated by the MoEFCC under the Solid Waste Management Rules, 2016. The EPR targets for paper waste management have been set by the CPCB for the following categories:

Currently, there are several companies in India that have implemented EPR policies for paper waste, including ITC, Hindustan Unilever, Nestle, Coca-Cola, etc. These companies have tie-ups with authorized recyclers to collect and dispose of their paper waste.

HUL is one of the largest fast-moving consumer goods (FMCG) companies in India, with a wide range of products in the personal care, home care, and food and beverages categories. The company has committed to achieving 100% plastic waste collection and management by 2025, as part of its larger goal to become a “circular economy” business. To achieve this target, HUL has launched several initiatives, including setting up a network of plastic waste collection and recycling infrastructure, working with waste pickers and recyclers, and promoting awareness among consumers about responsible plastic waste management.

P&G is a multinational consumer goods company with a wide range of products in the personal care, home care, and health care categories. The company has committed to achieving 100% recyclable or reusable packaging by 2030, as part of its “Ambition 2030” sustainability goals. To achieve this target, P&G is investing in research and development to find innovative packaging solutions, working with suppliers to source more sustainable materials, and partnering with recycling companies to improve recycling infrastructure and processes.

ITC Limited is a diversified conglomerate with interests in the fast-moving consumer goods, agri-business, hotels, paperboards, and packaging industries. The company has set a target to achieve 100% plastic waste collection and management in its value chain by 2030, as part of its “Responsible and Sustainable Business” strategy. To achieve this target, ITC is investing in recycling infrastructure, promoting the use of sustainable materials in its packaging, and working with waste pickers and recyclers to promote responsible waste management.

Overall, while many of these companies have made significant progress towards their EPR targets, there is still a long way to go to achieve a truly sustainable and circular economy in India. Stronger regulatory frameworks, greater public awareness, and more effective partnerships between government, industry, and civil society will be needed to drive the necessary changes.

There are several home composting methods that can be used in India, depending on the amount of organic waste generated and the available space. Here are some common home composting methods with their respective capacity:

Pit Composting Method

Pit Composting MethodThis is a simple and low-cost method of composting that involves using any clay pot and adding organic waste materials.

The pot should be covered with soil and left to decompose for several months.

The capacity of a pot composting system can vary depending on the size of the pot.

But it is generally suitable for small households that generate less than 1-2 kg of organic waste per day.

This method involves using a container with a built-in mechanism to turn the compost, such as a compost tumbler.

The container is filled with organic waste and turned regularly to aerate the compost and speed up the decomposition process.

Tumbler composting is ideal for households that generate 1-2 kg of organic waste per day and can typically accommodate up to 20-30 liters of waste.

Worm Composting Method

Worm Composting MethodVermicomposting is a method of composting that uses earthworms to break down organic waste.

This method is suitable for households that generate up to 1 kg of organic waste per day and can be done in a small container, such as a plastic bin.

The capacity of a worm composting system depends on the size of the container, but it is generally recommended to start with a container that can hold 20-30 liters of waste.

This composting technique involves the use of anaerobic bacteria to ferment organic waste.

Here are the technical guidelines for bokashi composting:

A compost bin is a simple container that can be used to collect and compost organic waste. The bin

can be made from various materials, such as plastic, wood, or metal, and should have a lid to keep out pests and animals. The capacity of a compost bin can vary depending on its size, but it is typically suitable for households that generate up to 2-3 kg of organic waste per day.

It is important to note that the capacity of a home composting system can vary depending on factors such as the type of organic waste generated, the composting method used, and the climate conditions.

Aerobic composting involves providing oxygen to the compost pile to support the growth of aerobic microorganisms that break down the organic material and is typically faster than other methods and produces a higher-quality compost.

Here are the technical guidelines for aerobic composting:

Anaerobic composting is a process of decomposing organic waste in the absence of oxygen. It is a popular method of waste management in India, where large quantities of wet waste are generated daily.

Here are some technical guidelines for anaerobic wet waste composting in India:

By following these technical guidelines, anaerobic wet waste composting can be a successful and effective method of waste management in India.

Vermicomposting is a type of composting that involves the use of earthworms to decompose organic waste into nutrient-rich compost. In India, vermicomposting technology has gained popularity over the past few decades due to its several advantages such as the production of high-quality compost, reduction in waste generation and landfill disposal, and the potential for income generation.

Here are the technical guidelines for vermicomposting:

Some general guidelines on the capacity of vermicomposting units based on the quantity of waste to be processed:

A brief guide on Vermicomposting >

Mechanical composting is a method of composting organic waste that uses machines to speed up the process and produce high-quality compost. Here are some technical guidelines for implementing mechanical composting in India:

It is important to note that the guidelines may vary depending on the type of machine and the local regulations. Therefore, it is recommended to consult with experts and relevant authorities before implementing a mechanical composting system.

Incineration is a waste management technology that involves burning waste materials at high temperatures in a specially designed facility to generate energy in the form of heat or electricity. In India, incineration technology is increasingly being used for waste-to-energy (WTE) projects as a means of dealing with the country’s mounting waste management problem.

The Indian government has set a target of generating 100 MW of power from waste by 2020 and 300 MW by 2030. To achieve this goal, several WTE plants based on incineration technology have been constructed or are currently under construction in various cities in India.

The Indian government has developed guidelines for the setting up of waste-to-energy (WTE) plants, including those using incineration technology. These guidelines provide information on the technical, environmental, and regulatory aspects of WTE plants to ensure that they are designed, constructed, and operated to the highest standards.

According to the guidelines, the minimum capacity for a WTE plant based on incineration technology should be 100 tons per day. This is to ensure that the plant is economically viable and can generate sufficient electricity or heat to make the project financially sustainable. The guidelines do not specify a maximum capacity for incineration-based WTE plants.

In addition to the minimum capacity requirement, the guidelines also specify the following technical requirements for incineration-based WTE plants:

Overall, the Indian government is committed to promoting the development of sustainable waste management practices, including the use of WTE technologies such as incineration, to address the country’s waste management challenges.

Some of the notable incineration-based WTE plants in India are:

However, there are concerns about the environmental impacts of incineration technology, including the emission of air pollutants such as dioxins and furans, which are harmful to human health and the environment. Therefore, it is important to ensure that WTE plants using incineration technology are designed, constructed, and operated to the highest standards to minimize the release of harmful pollutants.

Overall, these methods are used for waste-to-energy projects in India, depending on the type of waste, technology availability, and local regulations. The goal of waste-to-energy is to reduce waste generation, recover energy from waste, and mitigate greenhouse gas emissions.

Pyrolysis is a thermal decomposition process that converts organic material into fuel or other useful products. In India, pyrolysis is used as a waste-to-energy technology to convert waste plastics, tires, and other non-biodegradable materials into useful products such as fuel oil, carbon black, and gas.

As per the Indian guidelines for the establishment of pyrolysis plants, the minimum plant capacity is 5 tons per day (TPD), while the maximum plant capacity is 500 TPD. However, the guidelines state that the plant capacity should be decided based on the availability of waste and the financial viability of the project. The guidelines also provide various technical and environmental requirements for the establishment of pyrolysis plants, such as the use of proper pollution control measures and the compliance with the applicable laws and regulations.

Some of the key guidelines and regulations related to pyrolysis in India are:

Overall, the guidelines and regulations related to pyrolysis in India aim to ensure that the technology is used in an environmentally sound and safe manner. Compliance with these guidelines is essential for the sustainable growth of pyrolysis as a waste-to-energy technology in India.

Gasification technology is a waste-to-energy (WTE) solution that converts dry waste into a usable gas called “syngas.” The gasification process involves heating dry waste to high temperatures in the presence of a limited amount of oxygen. This results in the production of syngas, which can be used as a fuel for various applications such as generating electricity, heating, and cooking. The remaining solid waste, known as slag, can be used for construction materials.

One of the advantages of gasification technology is that it can handle a wide range of waste types, including municipal solid waste, agricultural waste, and industrial waste. Another advantage of gasification technology is that it produces significantly fewer greenhouse gas emissions compared to traditional waste management methods such as landfilling. This is because the syngas produced by the gasification process can be used as a fuel source, reducing the need for fossil fuels.

Gasification technology also has the potential to create employment opportunities and generate revenue. For example, the syngas produced by the gasification process can be sold to industries as a fuel source, while the slag can be used for construction materials.

However, gasification technology is not without its challenges. The initial capital costs of setting up a gasification plant can be high, and the technology requires a skilled workforce to operate and maintain. Additionally, there may be issues with waste segregation and the quality of the feedstock used in the gasification process.

Overall, gasification technology has the potential to be an effective solution for managing dry waste in India. With the right policies and investments, it could help to reduce the amount of waste sent to landfills, while also providing a source of renewable energy and economic opportunities.

In India, there are several examples of gasification technology being used for dry waste management. Here are a few:

These are just a few examples of gasification technology being used for dry waste management in India. With the growing demand for sustainable waste management practices, it is likely that more such projects will be developed in the future.

Refuse-derived fuel (RDF) is a type of fuel produced by sorting and processing non-recyclable waste materials such as municipal solid waste (MSW), construction and demolition (C&D) waste, and industrial waste. In India, the government has introduced several policies and guidelines to promote the use of RDF as a sustainable energy source.

Some of the key policies and guidelines related to RDF production from MSW in India are:

Overall, the production of RDF from MSW is an important step towards the management of solid waste in India and the promotion of renewable energy. The government has taken several steps to promote RDF production, and there are several plants operating at different scales across the country. The SWM Scheme provides financial assistance to local bodies and municipalities for setting up RDF plants and waste-to-energy projects. The WTE Policy aims to promote the use of RDF as a fuel source for power generation, and encourages private sector participation in setting up RDF-based power plants. The Biomass Energy Policy provides incentives for the use of RDF as a renewable energy source, and encourages the development of decentralized RDF plants.

In terms of the scale of RDF plants in India, there are several examples of large-scale and small-scale plants.

Some of the large-scale plants include:

Some of the small-scale plants include:

Overall, the Indian government’s policies and guidelines promote the use of RDF as a sustainable energy source and provide incentives for setting up RDF plants of various scales.

Waste Recycling is the process of converting waste into new products. This method can be used for dry waste such as paper, plastic, metal, and glass. The technical guidelines for recycling include setting up collection points for recyclable materials, transporting them to the recycling facility, and ensuring that the recycled products meet the required quality standards.

India’s dry waste recycling market has been growing steadily over the years, driven by a combination of government initiatives, increasing public awareness, and the emergence of new technologies and business models. According to a report by the Central Pollution Control Board, India generates around 62 million tonnes of solid waste annually, out of which about 45 million tonnes is dry waste. However, only a small fraction of this waste is currently recycled, with the rest either ending up in landfills or being dumped in open spaces.

One of the key challenges facing the dry waste recycling market in India is the lack of proper waste management infrastructure and facilities. While there are some large-scale recycling plants in the country, a significant portion of the recycling is still done by small and informal players, who often lack the necessary technology, equipment, and regulatory compliance.

Despite these challenges, the dry waste recycling market in India has significant scalability potential, driven by several factors.

Overall, the dry waste recycling market in India is poised for significant growth in the coming years, driven by the country’s large and growing waste generation, increasing public awareness, and government support. However, this growth will require significant investment in infrastructure and technology, as well as the development of strong regulatory frameworks to ensure compliance and quality control.

Upcycling is the process of transforming waste materials or products that are no longer useful into new materials or products of better quality and value. In India, the upcycling market for dry waste has been gaining traction in recent years, with several organizations and individuals contributing to this growing industry.

Here are some facts and figures related to the upcycling market for dry waste in India:

India is home to various upcycling waste product industries and here are some examples of companies working in India:

Overall, upcycling waste product industries and companies in India are making a significant contribution towards reducing waste and creating a more sustainable future through circularity.

Waste pickers are Individuals collecting and sorting the waste at the landfills, along the roadside and at garbage vulnerable spots and having the only source of income through selling it further. Waste picker integration at critical junctures has tremendous potential.

“Waste picker” as term was first recognized in solid waste management rules 2016.

Waste picker means a person or groups of persons informally engaged in collection and recovery of reusable and recyclable solid waste from the source of waste generation the streets, bins, material recovery facilities, processing and waste disposal facilities for sale to recyclers directly or through intermediaries to earn their livelihood. Informal waste collector includes individuals, associations or waste traders who are involved in sorting, sale and purchase of recyclable materials.

The rules also emphasize, advice or suggests implementation on following things related to waste pickers.

In the current scenario waste pickers hold immense local intelligence being an active part of the recycling and waste management chain. Waste pickers have grown from being at 1st level of value chain i.e., being involved in collection of waste to being at 3rd level of value chain i.e., pre-processing and aggregators level.

Informal waste collector includes individuals, associations or waste traders who are involved in sorting, sale and purchase of recyclable materials. –

Well before the recognition; three organizations Stree Mukti Sanghatana (in 1980s), Kagad Kach Kachra Kashtakari Panchayat (in 1990s) and Chintan (in 2000s) had started working towards welfare and structuring the work of waste pickers in Mumbai, Pune and Delhi respectively.

Since then, there have been various pilot models for involving waste pickers in formal activities. It has been through these organizations that modules for waste pickers identification and waste picker integration were practiced and piloted in particular areas but have always been limited by geography, holistic view and lack of support from government to have sustainable, replicable business model. The concern is that the positive scenario is limited to a particular geography and particular group of waste pickers.

| Sr No | Existing models | Waste picker identification | Mode of integration | Uniqueness of the model |

| 1 | SWaCH Cooperative, Pune | Through extensive field survey Approach -offering a sustainable financial model along with dignity and bringing ahead the voice of the community for social justice. | Forming a cooperative of waste pickers DTDC-user fee basis model | Balanced model-providing WPs with social benefits from the government side along with a programmatic and structured waste of self-employment. |

| 2 | Hasirudala, Bangalore | Community of waste pickers was reached out with a view to bring in dignity to their work and formalizing the system Approach -need to formalize the system and have formal access to waste and dignify the existing occupation of waste picking | Following the Lok Adalat directive in 2011 BBMP issued occupation identity cards to waste pickers Scrap shops were enumerated It was further formalized by establishing DWCC (Dry waste collection centers) | A business model as a base has made it replicable and scalable |

| 3 | Indore Municipal Corporation | Individuals collecting and sorting the waste at the landfills, along the roadside and at chronic spots were identified as waste pickers | integration was done into formal systems of waste management across the value chain | |

| 4 | Stree Mukti Sanghatana | Community-based engagement-for being voice to various social concerns like child marriage, gender equity, rights of women etc. Approach- for inclusion was by connecting social issues faced by waste picker communities and skill development for the community | waste pickers engaged in various forms of waste management activities were enlisted and made aware of their rights and social inclusion and upliftment schemes by the government | The model acts as support to local governments to establish and structure dialogue with the existing waste pickers and also for waste pickers to have their representation in the right way |

| 5 | Ambikapur Municipal Corporation | Individuals collecting and sorting the waste at the landfills, along the roadside and at chronic spots were identified as waste pickers | given id cards along with defining job roles of individuals identified WPs were introduced as paid resources for waste collections, waste sorting and labor requirement for a waste processing unit | The model exhibits the case where waste pickers have been integrated as a workforce of the local government, where payment is based on month wages for skilled labour |

India faces significant challenges when it comes to managing its solid waste. The country generates approximately 62 million tonnes of municipal solid waste per year, and a large proportion of this waste is dry waste. Dry waste includes items such as paper, cardboard, plastic, glass, and metal that do not decompose easily.

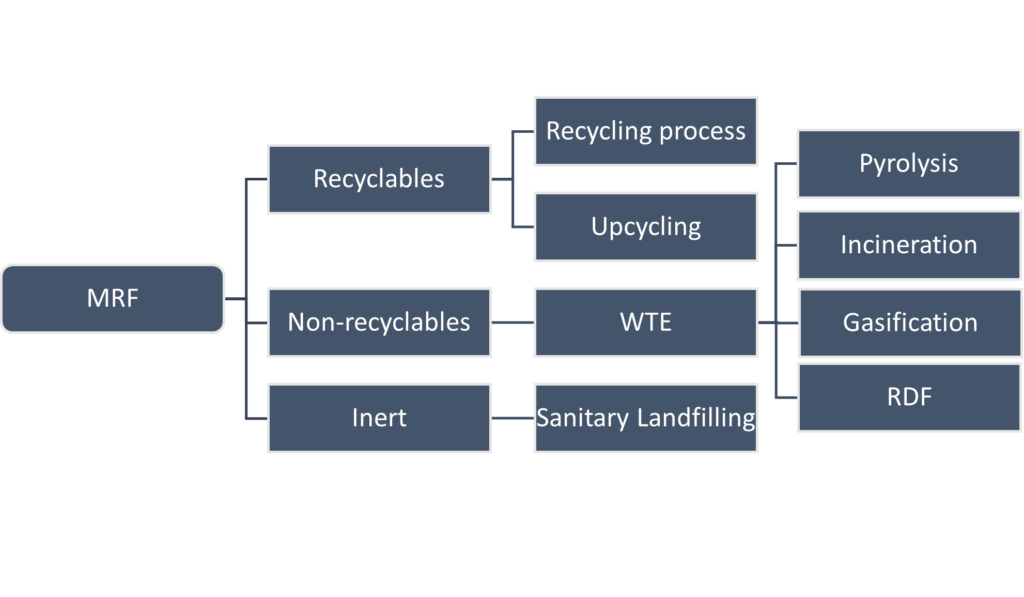

Material Recovery Facilities (MRFs) are specialized facilities that separate, process, and prepare recyclable materials for market. They use various techniques like shredding, sorting, and screening to separate different types of recyclables.

MRFs are facilities where mixed dry waste is sorted and separated into different categories using various technologies such as magnets, screens, and air classifiers. The technical guidelines for material recovery facilities include setting up the facility in a designated area, ensuring proper ventilation, providing safety equipment for workers, and maintaining a record of the amount and type of waste processed.

In India, the guidelines for setting up Material Recovery Facilities (MRFs) are provided by the Central Pollution Control Board (CPCB).

Overall, the guidelines for MRFs in India aim to promote safe and efficient handling of waste, reduce the amount of waste going to landfills, and promote the recycling of materials.

There are several types of Material Recovery Facilities (MRFs) in India, each with its own waste handling capacity and resource requirements. Here are some examples:

In terms of resource requirements, the guidelines for MRFs in India emphasize the need for adequate infrastructure, equipment, safety measures, and trained personnel. The Solid Waste Management Rules 2016 require that MRFs should have proper infrastructure, including sorting sheds, storage facilities, and safety equipment for workers.

The rules also require that MRFs should maintain records of the amount and type of waste processed and ensure compliance with environmental regulations. It is essential to conduct a detailed feasibility study before setting up an MRF to determine the appropriate technology and resource requirements based on local conditions and requirements.